Enterprise CNC Machining Specializes in CNC precision Machining of your custom parts made to your specifications.

Our machine shop facilities include the latest in CNC equipment for milling and turning as well as equipment to offer you other value added options, such as cutting, welding, and assembly.

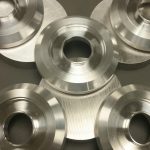

CNC Turning

- Live Tooling

- Conventional Lathes up to 25" in diameter

- Bar feed, high precision, CNC lathe machining centers

- Full C-axis design

- Castings, bar stock, plates and more

- Reliable output without operator intervention

CNC Milling

- Precision drilling

- Tapping

- Maximum work envelope of 30"

- Casting, bar stock, plates, and more

- Machining cells to reduce cost in high volume

- Fine tuned process with consistent results

Swiss Turning Services

- 20mm 5 axis with a 12 foot bar header

- Maximum diameter of 20mm

- Deep hole drilling

- Constantly evolving machining practices

- Trusted motor and alternator shafts

- Option of varying part length

Quality Control

Exceed customer expectations

Monitor and analyze product, process goals and suppliers

Continuously improve Product, processes and suppliers

Value Added Services

Finishing

Enterprise CNC Machining knows that a part is not complete without finishing. We work with qualified finishing suppliers to get your product finished hassle-free.

Light Assembly

Enterprise CNC Machining is equipped with the experience, people and equipment to do light assembly work ranging from simple to complex. Because the assembled components are often mating with CNC machined parts that we manufacture, we have better control of part fit and assembly function.

Welding

At Enterprise CNC Machining we can get the precision welding portion of you order done. Whether the part is large or small we can help you control cost, quality and save you precious time on your order.

Casting Development

Enterprise CNC Machining Company works with a qualified die casting specialist to develop aluminum die castings for your application. By incorporating our interchangeable mold we are able to minimize tooling cost and provide you with a quality product.